Insultherm® Tru-Fit

Economical Heat Treated, Fray-Resistant Fiberglass Sleeving

Insultherm® Tru-Fit is a braided fiberglass sleeving which has been heat treated and impregnated with an acrylic binder to reduce fraying and dusting, and improve usability and performance. FGL is engineered for applications where temperatures as high as 1,200°F may be encountered. Tru-Fit is used as primary insulation on low voltage applications such as leads in toasters, coffee makers, ranges and other appliances. Tru-Fit may also be used as insulation and protection for small heaters and resistors that operate at high temperatures, and to insulate over soldered connections when exposure to solder melt temperatures is possible. Insultherm® Tru-Fit provides a sturdy, long lasting and inexpensive insulation solution. It is flexible and expandable, and can easily be installed over applications with irregular shapes and tight turns.

- Cuts Easily With Scissors

- For High Temp - Low Voltage Applications

- Extremely Abrasion and Cut Resistant

- Will Not Burn or Support Combustion

- Operating Temps: -94°F to 1,202deg;F (-70°C to 650°C)

- RoHS Compliant & Halogen Free

- Resists Common Chemicals & Solvents

- UL Recognized: VW-1

- Excellent Low Temp Flexibility

- Melt Temp: 2,048°F/1,120°C

About The Insultherm® Family of Products

Insultherm® products are extremely high temperature resistant material commonly used as thermal protection for wires, cables and hoses that are subjected to continuous and extreme high temperature environments, such as engine manifolds and exhaust systems.

Insultherm®:This traditional sleeving is tough and durable, maintaining its tight structure under extreme vibration, abrasion, mechanical stress, and temperature variations.

Insultherm® Heavy Duty: This is a braided fiberglass sleeving made in a heavy wall construction with a high temp cord braided into the sleeving. Insultherm® HD is saturated with high temperature acrylic resins which adds rigidity and reduces fray when cut.

Insultherm® Tru-Fit: Tru-Fit is often used as primary insulation on low voltage applications such as leads in toasters, coffee makers, ranges, and other appliances. This product is available in a wider range of colors than standard Insultherm®.

Insultherm® Ultra Flex®: Ultra Flex® expands slightly, allowing it to slide easily over wires and follow curves and contours without binding. It is compatible with most bonding & saturation systems.

Insultherm® Ultra Flex® Pro: Ultra Flex® Pro cuts easily with scissors, and special heat treated construction minimizes fraying and dusting during assembly. The Increased wall thickness adds value to insulation.

Insultherm® Spark Plug Boots: These innovative sleeves offers high temperature protection in an easy slip on sleeve that will extend the life of expensive spark plug wires by protecting them where they need it most... at the boot. Just slip these 3/4” diameter double thickness (triple thick at the sewn end) sleeves over any spark plug cable and boot (even right angle boots) to protect them from engine temperatures up to 1,200°F.

Insultherm® Header Wrap: Insultherm® Header Wrap is an extremely high temperature resistant wrap commonly used to contain and manage hot gases in automotive and high performance headers and exhausts.

Insultherm® Header Wrap SI: This exhaust wrap is made from texturized amorphous silica filament yarn woven into a strong and flexible form. Because the yarn is texturized into a bulky form it provides excellent insulating values. Header Wrap SI is not made from leached fiberglass, resulting in a much more wear resistant finished product

Tips for Installing & Terminating Braided Sleeving

How To Determine What Diameter Sleeving You Need

Bundle the cords that you’ll be covering and measure the diameter of the bundle. If you want a snug fit, choose a braided sleeving option with a slightly smaller diameter than that of your cables. If you want a loose and flexible fit, choose a braided sleeving option with a diameter that is equal to or slightly larger than that of your cables. Keep in mind that braided sleeving loses 2% to 3% of its length when it expands. Be sure to plan accordingly!

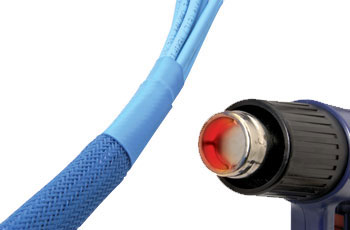

How To Terminate Sleeving with Heatshrink Tubing

Heatshrink Tubing is the ideal way to create a tight, professional finish on any wire, hose or cable management project. Once shrunk, the tubing will hold its reduced state, even at elevated temperatures. This application can be used to protect, color code, brand, or secure ends or sections of braided sleeving. A Heat Gun is required to properly apply heatshrink tubing. You can find a guide to the proper technique for working with heatshrink tubing Here.