Flexo® Noise Reduction

Full Coverage Protection with a Retro Look and Feel

Flexo® Noise Reduction is a biaxially braided hybrid sleeving combining monofilament and multifilament PET yarns to create a full coverage expandable sleeve that substantially reduces noise on wires, tubes and hoses. The lightweight, rugged construction also provides protection from abrasion and vibration that is far superior to foam harness sleeves. NR expands for easy installation over splices and connectors and is flexible enough for tight radius applications. The braided construction will not hold moisture and drains quickly when immersed. NR is used in body wiring harnesses, instrument panel and lighting wiring, cable & hose assemblies, and other limited access applications where noise reduction is desirable. In retrofit applications or when component or harness disassembly is impractical, our unique F6® Quiet hybrid wraparound sleeving provides identical noise reduction and protection characteristics.

- Cuts easily with hot knife

- Cut & abrasion resistant

- Expands Up to 150% or More

- Provides full coverage, professional look on finished product

- Resists common chemicals & solvents

- FAR 25, FMVSS 302 Approved

- Resists UV damage

- Special construction minimizes noise in enclosed applications

How to Choose The Correct Braided Sleeving

A lot of factors go into determining the correct braided sleeving wire protection method for your project. We’ve broken it down to help you narrow your search:

- Operating Temp: Is your wire harness going to be regularly exposed to extreme temperatures or possible flames? The operating temperature of your harness is a critical consideration when choosing sleeving to ensure that the sleeving you select can withstand the intended environment and provide adequate protection.

- Flexibility & Expansion Ratio: Flexibility is an important factor if your wire harness will be snaking around a lot of corners or curves or is frequently moving. Expansion ratio refers to the amount by which the diameter of a braided sleeving can increase when stretched. The expansion ratio of braided sleeving can vary depending on the material it is made of and the construction of the braiding.

- Material: Braided sleeving is available in a wide range of materials to provide different levels of abrasion, UV, and chemical resistance. Material also effects wire harness weight, EMI protection, and flexibility.

- Cutting Tool: Checking the recommended cutting tool for a sleeving product allows you to ensure you have the tools necessary for the job. If using a hot knife is not feasible for you, be sure to look for sleeving options that can be cut fraylessly with scissors.

- Sleeve Vs. Wrap: If you are consistently changing the wires & cables of your harness then a split wrap may be a better option for you than a solid sleeving product to installation is fast & easy.

- Industry & Environment:Techflex® braided sleeving products are organized into categories based on the most common uses of each product. If you work in a specific industry, visiting the corresponding product category may be a fast way to see applicable sleeving options for your project.

- Color choices: Braided sleeving is great for matching, color coding, and to identify wires & cables. If color coding is your goal, make sure the product you are considering offers enough colors for your project.

Tips for Installing & Terminating Braided Sleeving

How To Determine What Diameter Sleeving You Need

Bundle the cords that you’ll be covering and measure the diameter of the bundle. If you want a snug fit, choose a braided sleeving option with a slightly smaller diameter than that of your cables. If you want a loose and flexible fit, choose a braided sleeving option with a diameter that is equal to or slightly larger than that of your cables. Keep in mind that braided sleeving loses 2% to 3% of its length when it expands. Be sure to plan accordingly!

How To Cut Sleeving with a Hot Knife

To ensure a frayless, professional end on any installation, it is recommended that expandable braided sleeving be cut with a hot knife, rope cutter, or similar tool. We offer a wide variety of Hot Knives for different applications, including handheld knives, table knives, and replacement blades. Watch our video on Using A Hot Knife To Cut Braided Expandable Sleeving.

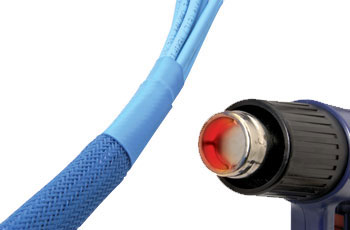

How To Terminate Sleeving with Heatshrink Tubing

Heatshrink Tubing is the ideal way to create a tight, professional finish on any wire, hose or cable management project. Once shrunk, the tubing will hold its reduced state, even at elevated temperatures. This application can be used to protect, color code, brand, or secure ends or sections of braided sleeving. A Heat Gun is required to properly apply heatshrink tubing. You can find a guide to the proper technique for working with heatshrink tubing Here.